Share

ECO POCKET 19EP

Soft synthetic pocket filter with incinerable plastic frame divided into two parts and filter bags in 100% thermobonded polypropylene fibre with progressive density. Efficiency class F9.

TECHNICAL CHARACTERISTICS AND LIMITS OF USE

- Colour: white

- Efficiency class (EN ISO 16890:2016) Group ISO ePM1 70%

- Efficiency class (CEN EN779): F9

- Average colorimetric efficiency: >95 %

- Maximum operating temperature: 90°C

- Relative humidity: 100%

- Initial pressure drop: 85 Pa

- Recommended final pressure drop: 450Pa

- Maximum pressure drop: 800Pa

- Dust collection capacity: 30 gr/m²

- Recommended filtering velocity: 0,15m/s

- Reaction to fire (DIN 53438/3): Class F1

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for sustainable buildings:

- LEED: IP, EA, MR, IN

- WELL: AIR, MATERIALS, COMMUNITY

- BREEAM: MAN, WST

FILTERING MEDIA

The fìltering media is made up of 100% thermobonded polypropylene fibre with progressive density. The chemicalphysical nature of the fibres and the welding technology ensure low pressure drops, maximum efficiency and maximum accumulation capacity.

APPLICATIONS

Filtration in air treatment units of civil buildings and in painting plants. Prefiltration of high-efficiency filters.

PRODUCT DISPOSAL

As the product is entirely made of plastic, it can be disposed of in one single solution. The CER code tor disposal is 150202.

DOWNLOAD TECHNICAL SHEET >>

Related products

-

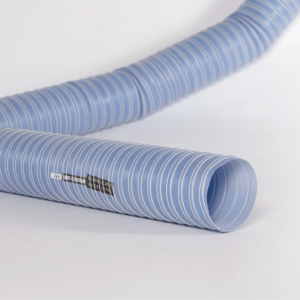

SA10 Mastersan

Flexible hose made of addivated polyolefin resins film with anti-bacterial, antimildew and anti-viral material protection with steel wire helix.

Read more -

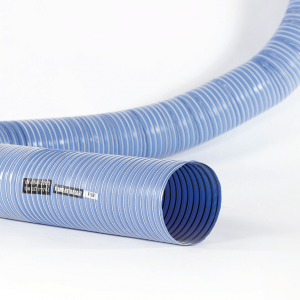

SA10/ESP Mastersan

Flexible hose produced with exclusive technology by TECNICA SRL.

Read more -

DSR – DSRS

Variable geometry diffuser developped for rooms with high ceilings where a long throw and a high induction ratio are required. Made up of a housing in which individually or simultaneously adjustable deflectors are fitted (if required) in order to change the direction of the air jet in relation to the thermal conditions required.

Read more -

DAM02C

Helical-effect diffuser with helically arranged adjustable deflectors with a high induction ratio (mixing capacity) between the injected and the ambient air. Made up of a plate with holes inside which adjustable plastic deflectors are housed.

Read more

ECO POCKET 19EP

Soft synthetic pocket filter with incinerable plastic frame divided into two parts and filter bags in 100% thermobonded polypropylene fibre with progressive density. Efficiency class F9.

TECHNICAL CHARACTERISTICS AND LIMITS OF USE

- Colour: white

- Efficiency class (EN ISO 16890:2016) Group ISO ePM1 70%

- Efficiency class (CEN EN779): F9

- Average colorimetric efficiency: >95 %

- Maximum operating temperature: 90°C

- Relative humidity: 100%

- Initial pressure drop: 85 Pa

- Recommended final pressure drop: 450Pa

- Maximum pressure drop: 800Pa

- Dust collection capacity: 30 gr/m²

- Recommended filtering velocity: 0,15m/s

- Reaction to fire (DIN 53438/3): Class F1

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for sustainable buildings:

- LEED: IP, EA, MR, IN

- WELL: AIR, MATERIALS, COMMUNITY

- BREEAM: MAN, WST

FILTERING MEDIA

The fìltering media is made up of 100% thermobonded polypropylene fibre with progressive density. The chemicalphysical nature of the fibres and the welding technology ensure low pressure drops, maximum efficiency and maximum accumulation capacity.

APPLICATIONS

Filtration in air treatment units of civil buildings and in painting plants. Prefiltration of high-efficiency filters.

PRODUCT DISPOSAL

As the product is entirely made of plastic, it can be disposed of in one single solution. The CER code tor disposal is 150202.

DOWNLOAD TECHNICAL SHEET >>

Share

Related products

-

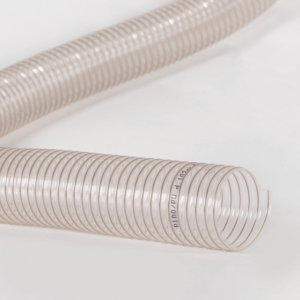

KF125/R

Synthetic flat filter cell far fan coils with support and containment frame in 3mm-diameter drawn rod and double electrowelded galvanised steel wire mesh that supports the 10×10 honeycomb filter fabric.

Read more -

DCMQ

High-induction circular diffuser with adjustable cones made up of concentric truncated cone profiles on a square panel, suitable for installation on false ceilings with 600×600 panels. Height adjustable by means of an adjustment screw in order to change the direction of the air jet in relation to the required thermal conditions.

Read more