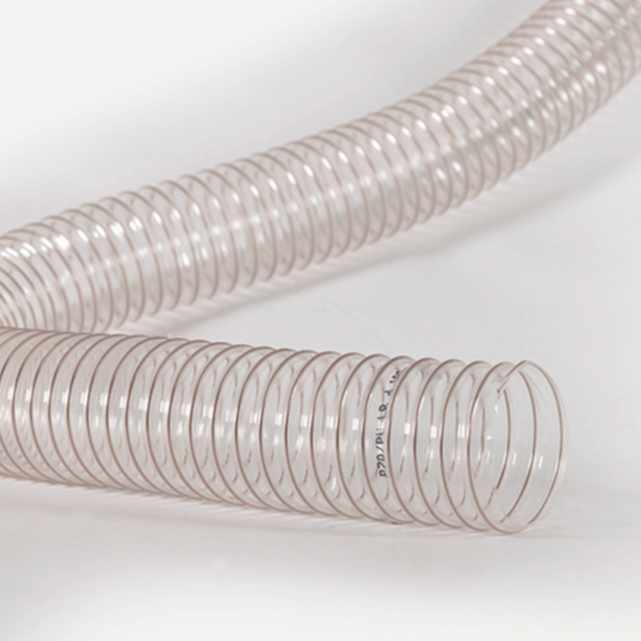

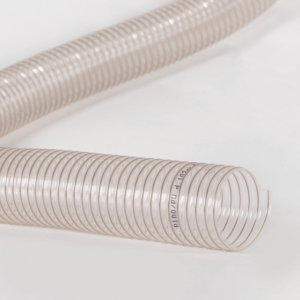

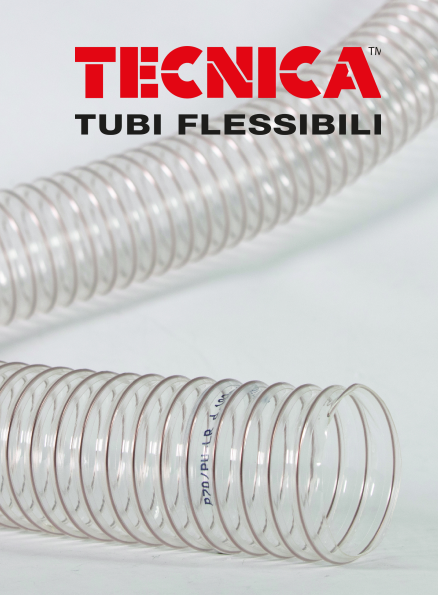

P70/PU (ETHER BASE)

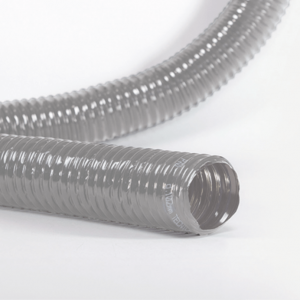

Flexible hose made of a polyurethane (PU-ether) sheet (th. 0,45 mm) and embedded copper-plated steel wire helix with thick pitch.

The main characteristic of this hose is its great resistance to abrasion and cutting (5-6 times greater than rubber and 7 times greater than PVC). Great flexibility and compressibility.

SPECIFICATIONS

- COLOUR: Transparent (blue on request)

- LENGTHS: 10 m standard

(coils of 15 and 20m up to ∅ 200 mm on request) - OPERATING TEMPERATURE: -40°C to +90°C

(+ 125°C peak) - AXIAL C0MPRESSIBILITY: 5:1

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for sustainable buildings:

- LEED: MR

- WELL: MATERIALS

APPLICATIONS

Suction of chips, wood and other material, dust, pneumatic conveyance of textile fibres, paper, etc.

MAINTENANCE

Periodically check the state of wear of the hose and immediately replace it if damaged or broken. Pay maximum attention to the duct operating temperatures.

DOWNLOAD TECHNICAL SHEET >>

Related products

-

S98

Flexible hose made of polyamide fabric impregnated with Santoprene and embedded steel wire helix. Particularly indicated in presence of aggressive fumes.

Read more -

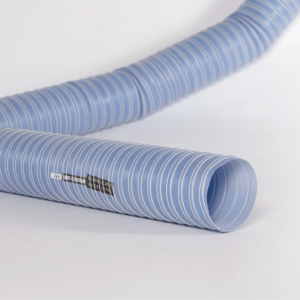

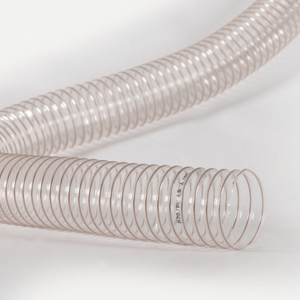

P70

Flexible hose made of special soft and flame retardant PVC sheet (0,45mm) and embedded steel wire helix.

Read more -

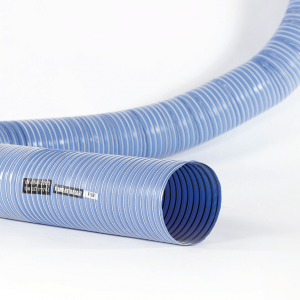

L94

Flexible hose made of a special polyamide fabric, double PVC-coating with high mechanical strength and embedded steel wire helix.

Read more -

AC

Light flexible hose made of polyester fabric coated with addivated polyolefin resins and steel wire helix.

Read more

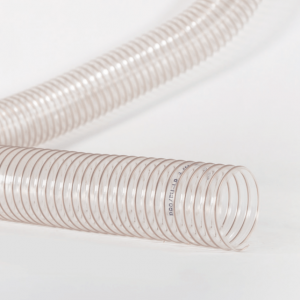

P70/PU (ETHER BASE)

Flexible hose made of a polyurethane (PU-ether) sheet (th. 0,45 mm) and embedded copper-plated steel wire helix with thick pitch.

The main characteristic of this hose is its great resistance to abrasion and cutting (5-6 times greater than rubber and 7 times greater than PVC). Great flexibility and compressibility.

SPECIFICATIONS

- COLOUR: Transparent (blue on request)

- LENGTHS: 10 m standard

(coils of 15 and 20m up to ∅ 200 mm on request) - OPERATING TEMPERATURE: -40°C to +90°C

(+ 125°C peak) - AXIAL C0MPRESSIBILITY: 5:1

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for sustainable buildings:

- LEED: MR

- WELL: MATERIALS

APPLICATIONS

Suction of chips, wood and other material, dust, pneumatic conveyance of textile fibres, paper, etc.

MAINTENANCE

Periodically check the state of wear of the hose and immediately replace it if damaged or broken. Pay maximum attention to the duct operating temperatures.

DOWNLOAD TECHNICAL SHEET >>

Related products

-

EX1 GAS AUTO

Lightweight and crushproof flexible hose for reels. Suitable for suction of exhaust gas of petrol and Diesel powered engines. The hose is made of TPK-coated polyester and PA6.6 flexible helix covered with TPK profile.

Read more -

P70 OIL

Flexible hose made of special PVC compound sheet (0.45mm) soft and elastic. Embedded steel wire helix. Good resistance to oily fumes.

Read more