Share

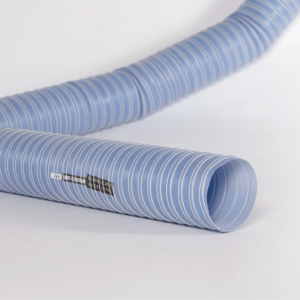

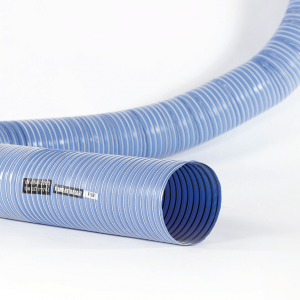

F10/ESP THERM

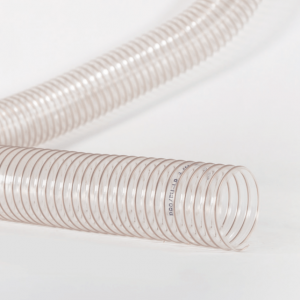

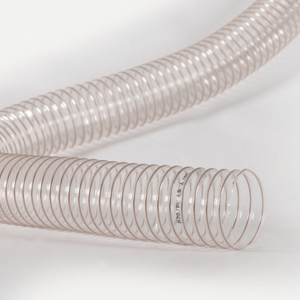

Flexible hose produced with exclusive technology by TECNICA SRL made of:

– Addivated polyolefin resins film.

– Thermo-insulating coating in netted and closed-cell of polyethylene foam.

– External protection in addivated polyolefin resins film.

– Embedded steel wire helix.

– Thermo-insulating covering in polyester fibre (th. 25mm/16kg/m3).

– Outer anti-steam protection in additivated polyolefin resin.

The assembly of materials for the construction of the flexible conduit does not require the use of chemical agents, glues or adhesives.

Insulation:

- 25mm / 16kg/m3 – standard

- 50mm / 16kg/m3 – on request

Thermal resistivity at 20°C

- R = 0,66m2 K/W (UNI EN 12664:2002)

SPECIFICATIONS

- COLOUR: Black external / Grey internal

- LENGTHS: 10m standard

- DIAMETERS OF PRODUCTION: from 70 to 254 mm

- OPERATING TEMPERATURES: -20°C +90°C (+115°C peaks)

- BENDING RADIUS: 1,2 – 1,8 x ø

- AIR SPEED: max 20m/sec

- PRESSURE: max 200 mm ca

- FIRE REACTION

CLASS IT:

Internal/external Film: Class 1 (D.M. 26/06/84)

PES foam: Class 1 (D.M. 26/06/84)

CLASS EU:

Thermal insulation:

class B-s2, d0 (EN 13501-1:2009)

Sheath:

class B-s1, d0 (EN 13501-1:2009)

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for sustainable

buildings:

- LEED: IP, EA, MR

- WELL: MATERIALS, COMMUNITY

- BREEAM: MAN, ENE, WST

APPLICATIONS

Air conditioning, Mechanical ventilation simple or double flow, Reduction of condensation and heat dispersion, Air conditioning plants for transport, agricultural and industrial use.

DOWNLOAD TECHNICAL SHEET >>

Related products

-

KF100

Synthetic flat filter celi for fan coils with U-section galvanised steel support frame and double electrowelded galvanised wire mesh that supports the FiltraSan™ sanitizing filter in AT100 series thermobonded staple fabric with a basis weight of 100 gr/m² and a thickness of 5-10 mm.

Read more -

DSRQ – DSRSQ

Variable geometry diffuser on 597×597 mm panel developed for rooms with high ceilings where a long throw and a high induction ratio are required. Made up of a half-housing in which individually or simultaneously adjustable deflectors are fitted (if required) in order to change the direction of the air jet in relation to the thermal conditions required.

Read more -

DAM31

Helical-effect diffuser with helically arranged adjustable deflectors with a high induction ratio (mixing capacity) between the injected and the ambient air. Made up of a plate with holes inside which adjustable plastic deflectors are housed.

Read more -

AC

Light flexible hose made of polyester fabric coated with addivated polyolefin resins and steel wire helix.

Read more

F10/ESP THERM

Flexible hose produced with exclusive technology by TECNICA SRL made of:

– Addivated polyolefin resins film.

– Thermo-insulating coating in netted and closed-cell of polyethylene foam.

– External protection in addivated polyolefin resins film.

– Embedded steel wire helix.

– Thermo-insulating covering in polyester fibre (th. 25mm/16kg/m3).

– Outer anti-steam protection in additivated polyolefin resin.

The assembly of materials for the construction of the flexible conduit does not require the use of chemical agents, glues or adhesives.

Insulation:

- 25mm / 16kg/m3 – standard

- 50mm / 16kg/m3 – on request

Thermal resistivity at 20°C

- R = 0,66m2 K/W (UNI EN 12664:2002)

SPECIFICATIONS

- COLOUR: Black external / Grey internal

- LENGTHS: 10m standard

- DIAMETERS OF PRODUCTION: from 70 to 254 mm

- OPERATING TEMPERATURES: -20°C +90°C (+115°C peaks)

- BENDING RADIUS: 1,2 – 1,8 x ø

- AIR SPEED: max 20m/sec

- PRESSURE: max 200 mm ca

- FIRE REACTION

CLASS IT:

Internal/external Film: Class 1 (D.M. 26/06/84)

PES foam: Class 1 (D.M. 26/06/84)

CLASS EU:

Thermal insulation:

class B-s2, d0 (EN 13501-1:2009)

Sheath:

class B-s1, d0 (EN 13501-1:2009)

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for sustainable

buildings:

- LEED: IP, EA, MR

- WELL: MATERIALS, COMMUNITY

- BREEAM: MAN, ENE, WST

APPLICATIONS

Air conditioning, Mechanical ventilation simple or double flow, Reduction of condensation and heat dispersion, Air conditioning plants for transport, agricultural and industrial use.

DOWNLOAD TECHNICAL SHEET >>

Share

Related products

-

SA10 THERM Mastersan

Flexible hose made of addivated polyolefin resins film with anti-bacterial, antimildew and anti-viral material protection with steel wire helix. Thermoinsulating covering in polyester fibre (thickness 25mm/16kg/m3). Outer aluminized film protection (flame retardant).

Read more -

DCSC

Circular diffuser with adjustable cones made up of concentric truncated cone profiles, adjustable in height by means of a screw in order to change the direction of the air jet in relation to the required

Read more