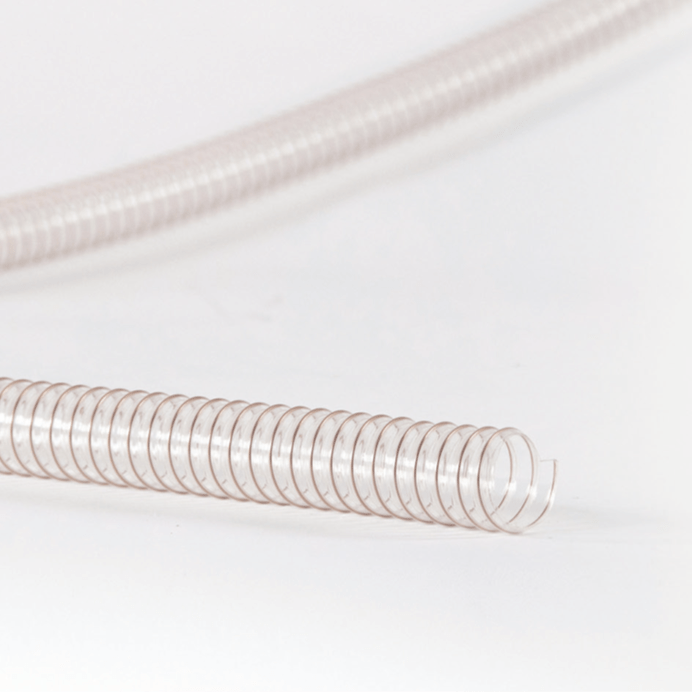

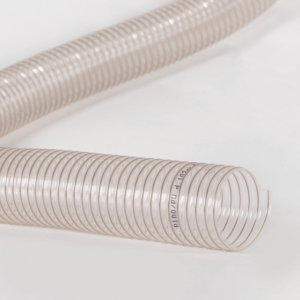

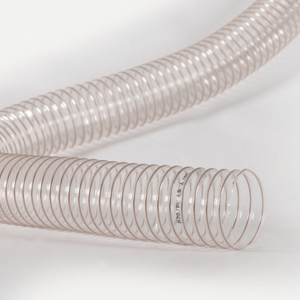

SM-PU (ETHER BASE)

The SM-PU hose (PU-ether) line was designed to respond to the need far small diameters.

The main characteristic of this product is the reduced elix pitch (10 mm).

SPECIFICATIONS

- COLOUR: Transparent

- LENGTHS: 15 m standard (10m on request)

- OPERATING TEMPERATURE: -40°C to +90°C

(+125°C peak)

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for sustainable buildings:

- LEED: MR

- WELL: MATERIALS

APPLICATIONS

Suction of chips, wood and other material, dust, pneumatic conveyance of textile fibres, paper, etc.

MAINTENANCE

Periodically check the state of wear of the hose and immediately replace it if damaged or broken. Pay maximum attention to the duct operating temperatures.

DOWNLOAD TECHNICAL SHEET >>

Related products

-

EDU/45

Flexible hose made of a TPE thermoplastic sheet and copper-plated steel wire helix.

The hose is particularly suitable for suction of aggressive fumes even in the presence of different kind of acids, bases and solvents.

Read more -

P407/PU-LR (ESTER BASE)

Flexible hose made of a polyurethane (PU-ester) sheet (th. 0,40mm) and embedded copper-plated steel wire helix with thick pitch.

Read more -

P70 OIL

Flexible hose made of special PVC compound sheet (0.45mm) soft and elastic. Embedded steel wire helix. Good resistance to oily fumes.

Read more -

L94 Antistatic

Flexible hose made of a special polyamide fabric, double antistatic PVC-coating with high mechanical strength and embedded steel wire helix.

Read more

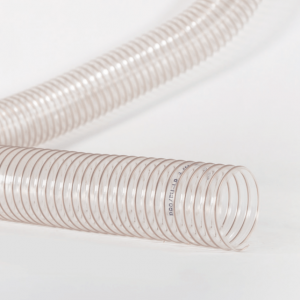

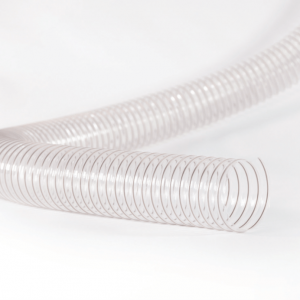

SM-PU (ETHER BASE)

The SM-PU hose (PU-ether) line was designed to respond to the need far small diameters.

The main characteristic of this product is the reduced elix pitch (10 mm).

SPECIFICATIONS

- COLOUR: Transparent

- LENGTHS: 15 m standard (10m on request)

- OPERATING TEMPERATURE: -40°C to +90°C

(+125°C peak)

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for sustainable buildings:

- LEED: MR

- WELL: MATERIALS

APPLICATIONS

Suction of chips, wood and other material, dust, pneumatic conveyance of textile fibres, paper, etc.

MAINTENANCE

Periodically check the state of wear of the hose and immediately replace it if damaged or broken. Pay maximum attention to the duct operating temperatures.

DOWNLOAD TECHNICAL SHEET >>

Related products

-

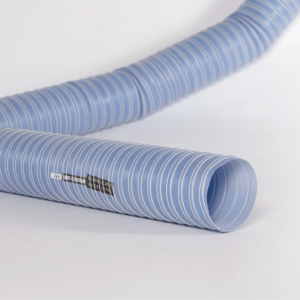

M12-HT

Flexible hose made of polyester fabric, special PU for high temperatures coated, embedded steel wire helix.

Thanks to the special execution this hose results light but very flexible, with high resistance to tears and perforations.

Read more -

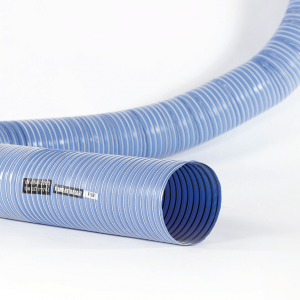

M90/FV

Flexible hose made of fibreglass fabric, PVC coated on both sides, embedded steel wire helix. This special execution allows the usage in every suction and ventilation installations, even with moving parts.

Read more