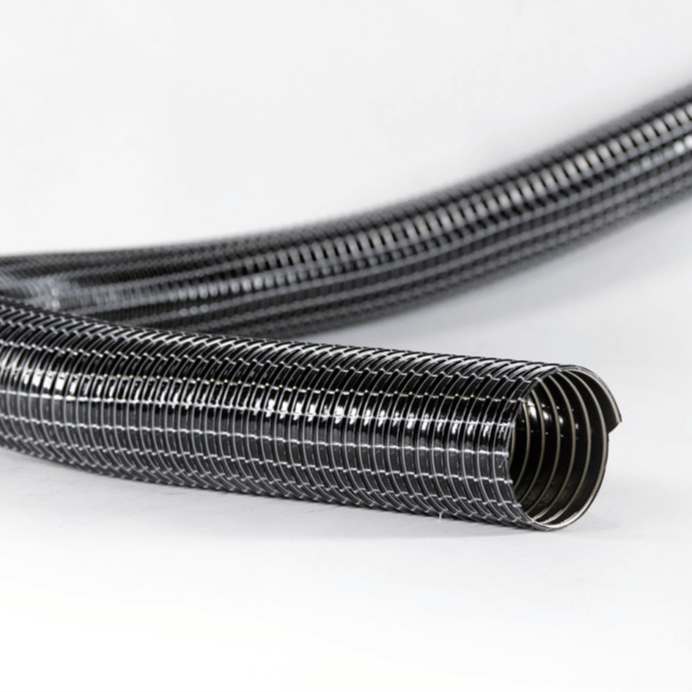

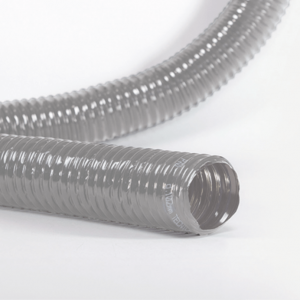

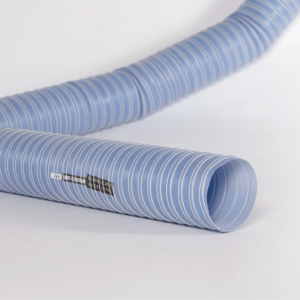

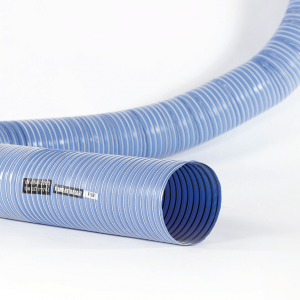

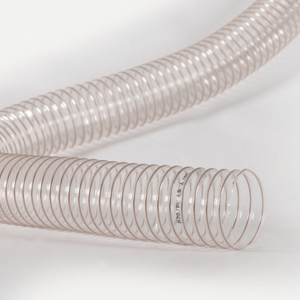

PVC-FLEX Superelastic

Flexible hose made of two PVC sheets (black internal layer and transparent external layer) with reinforcement spiral between the two layers. Internal plastic-coated steel helix. Very lightweight and extremely flexible hose with excellent resistance to vacuum.

SPECIFICATIONS

- COLOUR: Black with white spiral

- LENGTHS: 15 m standard (10 m standard from Ø 70mm)

- OPERATING TEMPERATURE: 0°C to +85°C (peak)

APPLICATIONS

Vacuum cleaning in the industrial sector, textile industry and for community centers, boats and caravans. Machine tools.

MAINTENANCE

Periodically check the state of wear of the hose and immediately replace it if damaged or broken. Pay maximum attention to the duct operating temperatures.

DOWNLOAD TECHNICAL SHEET >>

Related products

-

P8

Flexible hose made of a layer of neoprene-coated fibreglass fabric, internal and visible copper-plated steel wire helix and external fibreglass card.

Read more -

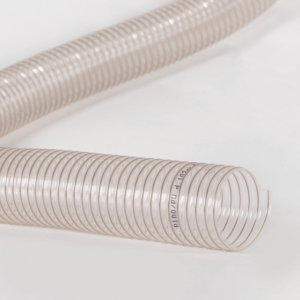

P150/PU (ESTER BASE)

Flexible hose made of a polyurethane (PU-ester) sheet(th. 1,10 mm) and embedded copper-plated steel wire helix.

Read more -

P80/PU (ESTER BASE)

Flexible hose made of a polyurethane (PU-ester) sheet (th. 0,60 mm) and embedded copper-plated steel wire helix.

Read more -

L94

Flexible hose made of a special polyamide fabric, double PVC-coating with high mechanical strength and embedded steel wire helix.

Read more

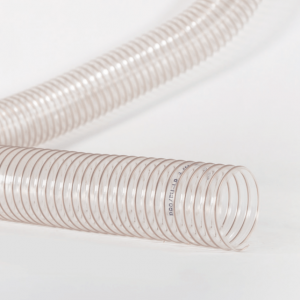

PVC-FLEX Superelastic

Flexible hose made of two PVC sheets (black internal layer and transparent external layer) with reinforcement spiral between the two layers. Internal plastic-coated steel helix. Very lightweight and extremely flexible hose with excellent resistance to vacuum.

SPECIFICATIONS

- COLOUR: Black with white spiral

- LENGTHS: 15 m standard (10 m standard from Ø 70mm)

- OPERATING TEMPERATURE: 0°C to +85°C (peak)

APPLICATIONS

Vacuum cleaning in the industrial sector, textile industry and for community centers, boats and caravans. Machine tools.

MAINTENANCE

Periodically check the state of wear of the hose and immediately replace it if damaged or broken. Pay maximum attention to the duct operating temperatures.