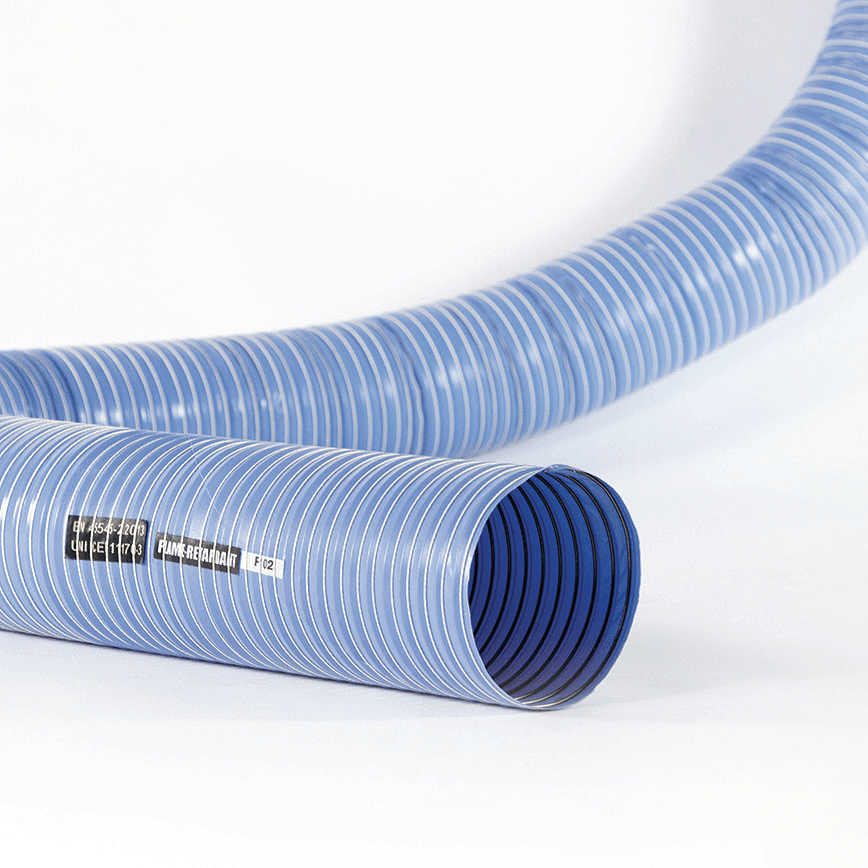

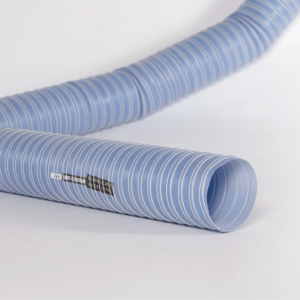

P4-FR

Flexible hose made of a layer of flame retardant silicone-coated fibreglass fabric, internal and visible copper-plated steel wire helix and external fibreglass cord.

SPECIFICATIONS

- COLOUR: Light blue

- LENGTHS: 4 m. standard

- OPERATING TEMPERATURE: -60°C +270°C (+300°C peak)

- AXIAL COMPRESSIBILITY: 30%

- FIRE REACTION: EN 45545-2:2013 + A1:2015 (R1/HL1,HL2)

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for sustainable buildings:

- LEED: MR

- WELL: MATERIALS

APPLICATIONS

Suction, extraction and blowing of air even with dusty particles in presence of high temperatures.

MAINTENANCE

Periodically check the state of wear of the hose and immediately replace it if damaged or broken. Pay maximum attention to the duct operating temperatures.

DOWNLOAD TECHNICAL SHEET >>

Related products

-

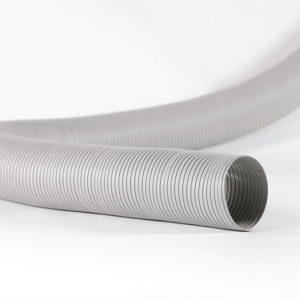

PLASTIROLL type A

Flexible hose made of a sturdy and special PVC profile, helical spiralled. The clockwise or anticlockwise spiral rotation allows to change the diameter by up to 35% more or less compared to the nominal diameter.

Read more -

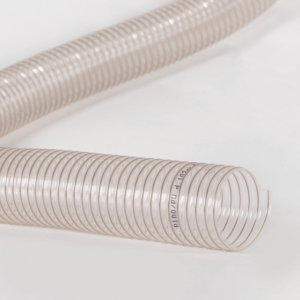

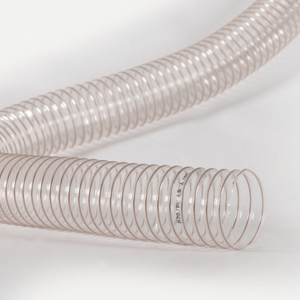

P70/PU (ESTER BASE)

Flexible hose made of a polyurethane (PU-ester) sheet (th. 0,45 mm) and embedded copper-plated steel wire helix with thick pitch.

Read more -

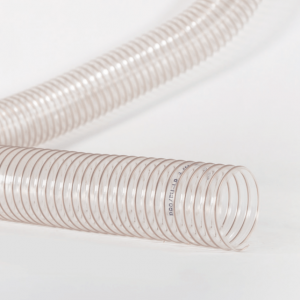

P60/PU-LR (ESTER BASE)

Flexible hose made of a polyurethane (PU-ester) sheet (th. 0,45 mm) and embedded copper-plated steel wire helix with large pitch.

Read more -

M90/P-AS

Flexible hose made of polyamide fabric, antistatic PVC-coated, R <= 10⁸ Ohm, on both sides, embedded steel wire helix. This special execution allows the usage in every suction and ventilation installations, even with moving parts.

Read more

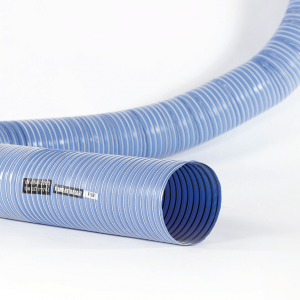

P4-FR

Flexible hose made of a layer of flame retardant silicone-coated fibreglass fabric, internal and visible copper-plated steel wire helix and external fibreglass cord.

SPECIFICATIONS

- COLOUR: Light blue

- LENGTHS: 4 m. standard

- OPERATING TEMPERATURE: -60°C +270°C (+300°C peak)

- AXIAL COMPRESSIBILITY: 30%

- FIRE REACTION: EN 45545-2:2013 + A1:2015 (R1/HL1,HL2)

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for sustainable buildings:

- LEED: MR

- WELL: MATERIALS

APPLICATIONS

Suction, extraction and blowing of air even with dusty particles in presence of high temperatures.

MAINTENANCE

Periodically check the state of wear of the hose and immediately replace it if damaged or broken. Pay maximum attention to the duct operating temperatures.

DOWNLOAD TECHNICAL SHEET >>

Related products

-

P407/PU-LR (ESTER BASE)

Flexible hose made of a polyurethane (PU-ester) sheet (th. 0,40mm) and embedded copper-plated steel wire helix with thick pitch.

Read more -

M90/P-AS

Flexible hose made of polyamide fabric, antistatic PVC-coated, R <= 10⁸ Ohm, on both sides, embedded steel wire helix. This special execution allows the usage in every suction and ventilation installations, even with moving parts.

Read more