Share

SOFT POCKET 25TF

Soft synthetic pocket filter with U-section galvanised steel frame and filter bags in 200 g/m² polyester fibre with progressive density on the air outlet side. Efficiency class MS.

TECHNICAL CHARACTERISTICS AND LIMITS OF USE

- EN ISO 16890:2016 Group ISO ePM10 60%

- Efficiency class (CEN EN779-2012): M5

- Average gravimetrie efficiency: 96 %

- Filter fabric basis weight: 200 gr/m²

- Thickness: 10-12 mm

- Maximum operating temperature: 100°c

- Relative humidity: 100%

- Initial pressure drop: 58 Pa

- Recommended final pressure drop: 250Pa

- Maximum pressure drop: 400P

- Dust collection capacity: 730 gr/m²

- Recommended frontal velocity: 1,5 m/s

- Reaction to fire (DIN 53438/3): Class F1

- DIN4102/1: B2

- NF-F-16-101: M1

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for sustainable buildings:

- LEED: IP, EA, MR

- WELL: AIR, MATERIALS, COMMUNITY

- BREEAM: MAN, WST

FILTERING MEDIA

The filtering media is composed of polyester fibre with progressive density on the air outlet side. The chemical-physical nature of the fibres and the separators welded to the inside of each bag ensure low pressure drops, maximum accumulati on capacity and a larger filtering surface.

APPLICATIONS

Filtration in air treatment units of civil buildings and in painting plants. Prefiltration of high-efficiency filters.

PRODUCT DISPOSAL

Dispose of the product by separating the metal part from the filtering part. The CER code for disposal of the metal part is 120101. The CER code for disposal of the filtering part is 150202.

DOWNLOAD TECHNICAL SHEET >>

Related products

-

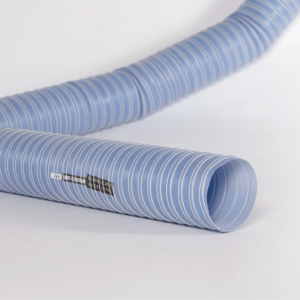

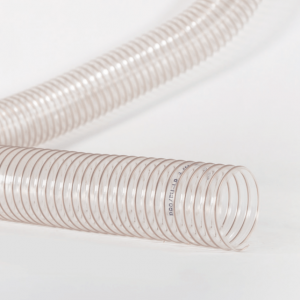

SA10 THERM Mastersan

Flexible hose made of addivated polyolefin resins film with anti-bacterial, antimildew and anti-viral material protection with steel wire helix. Thermoinsulating covering in polyester fibre (thickness 25mm/16kg/m3). Outer aluminized film protection (flame retardant).

Read more -

SA10/ESP SLEEVE Mastersan

Insulating sleeve produced with exclusive technology by TECNICA SRL.

Read more -

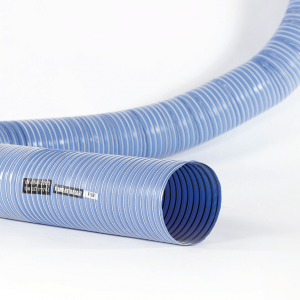

DCMC

Flexible hose made of reinforced polyamide fabric, PVC-coated on both sides, and embedded steel wire helix.

Read more -

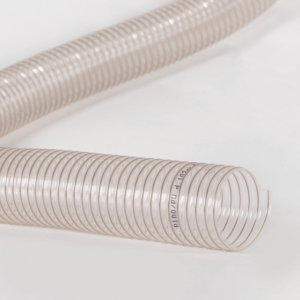

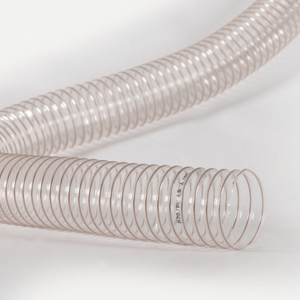

AC

Light flexible hose made of polyester fabric coated with addivated polyolefin resins and steel wire helix.

Read more

SOFT POCKET 25TF

Soft synthetic pocket filter with U-section galvanised steel frame and filter bags in 200 g/m² polyester fibre with progressive density on the air outlet side. Efficiency class MS.

TECHNICAL CHARACTERISTICS AND LIMITS OF USE

- EN ISO 16890:2016 Group ISO ePM10 60%

- Efficiency class (CEN EN779-2012): M5

- Average gravimetrie efficiency: 96 %

- Filter fabric basis weight: 200 gr/m²

- Thickness: 10-12 mm

- Maximum operating temperature: 100°c

- Relative humidity: 100%

- Initial pressure drop: 58 Pa

- Recommended final pressure drop: 250Pa

- Maximum pressure drop: 400P

- Dust collection capacity: 730 gr/m²

- Recommended frontal velocity: 1,5 m/s

- Reaction to fire (DIN 53438/3): Class F1

- DIN4102/1: B2

- NF-F-16-101: M1

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for sustainable buildings:

- LEED: IP, EA, MR

- WELL: AIR, MATERIALS, COMMUNITY

- BREEAM: MAN, WST

FILTERING MEDIA

The filtering media is composed of polyester fibre with progressive density on the air outlet side. The chemical-physical nature of the fibres and the separators welded to the inside of each bag ensure low pressure drops, maximum accumulati on capacity and a larger filtering surface.

APPLICATIONS

Filtration in air treatment units of civil buildings and in painting plants. Prefiltration of high-efficiency filters.

PRODUCT DISPOSAL

Dispose of the product by separating the metal part from the filtering part. The CER code for disposal of the metal part is 120101. The CER code for disposal of the filtering part is 150202.

DOWNLOAD TECHNICAL SHEET >>

Share

Related products

-

KC35

Synthetic flat filter celi tor fan coils with U-section galvanised steel frame and double electrowelded galvanised wire mesh that supports the filter fabric in thermobonded synthetic polyester staple fibre impregnateci with AC CARBON series active carbons with a basis weight of 200 g/m² and a thickness of 5-10 mm.

Read more -

DMU

Diffuser with individually adjustable micro nozzles with high output velocity and low sound in order to obtain extensive penetration depths of the room to be air conditioned.

Read more