Share

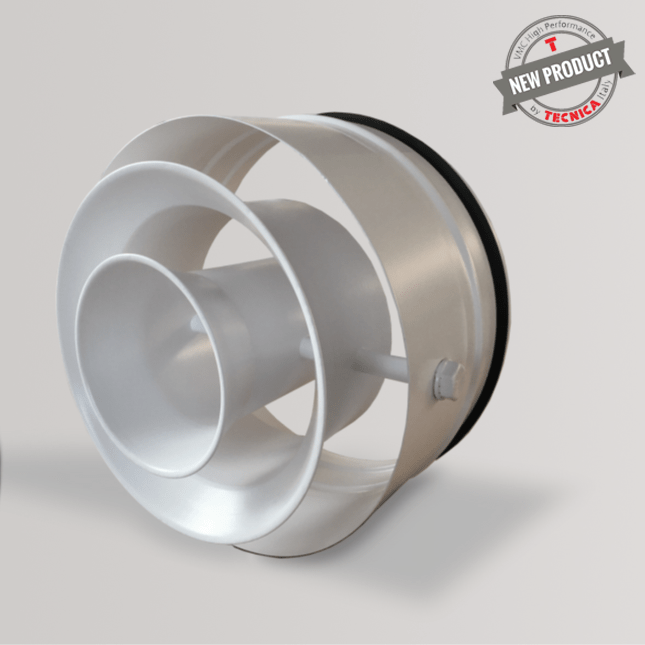

DHT

High-induction adjustable conical nozzle diffuser with direct duct mounting and EPDM sealing gasket. The central body can be easiliy adjusted or rotated 180° for maximum throw.

- INSTALLATION HEIGHT:: up to 25/30m

- APPLICATION: cooling and heating for wide areas

SPECIFICTIONS

• MATERIAL: Pickled Steel

• SURFACE FINISH: epoxy powder coating resistant to impact and abrasion

• COLOUR: RAL white 9010 glossy, 9016 glossy, 9003 mat. On request, coating in nonstandard RAL colours

• FASTENING: by means of screws positioned on the diffuser neck

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for suistainable buildings:

- LEED: IP, EA, MR

- WELL: MATERIALS, COMMUNITY

- BREEAM: MAN, WST

INSTALLATION

Adjustments and maintenance are simple to perform. The central conical nozzles are easily removable by acting on the external nuts. The channel fixing is carried out by means of screws from the neck of the diffuser.

ADJUSTMENT

Central conical nozzles in standard position: optimal position in cooling conditions in order to obtain a shallower throw with a greater amplitude. With this configuration you have the best conditions of pressure drop, speed and sound level. The maximum temperature difference (DT) between the ambient air and the air coming out of the diffuser to obtain the optimal induction conditions is 12 ° C.

Central conical nozzles rotated 180 ° inwards: optimal position for particularly high rooms, up to 25/30 m and in heating conditions as a maximum vertical throw is obtained which opposes the convective motion of the air in the environment .

DOWNLOAD TECHNICAL SHEET >>

Related products

-

KF100/R

Synthetic flat filter cell far fan coils with U-section galvanised steel support and containment frame and double electrowelded galvanised wire mesh that supports the 10x 10 honeycomb filter fabric.

Read more -

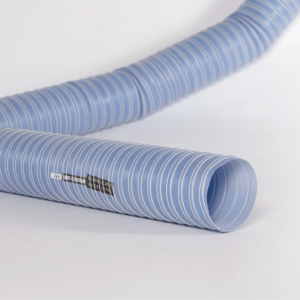

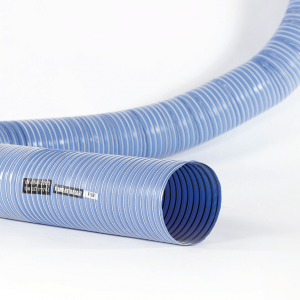

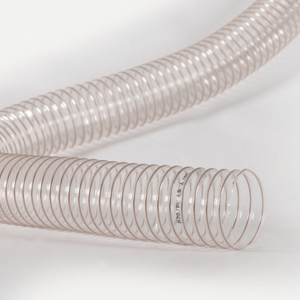

AR10 THERM MASTERSAN

Flexible hose made of addivated polyolefin resins film reinforced with polyester mesh with anti-bacterial, anti-mildew and anti-viral material protection with steel wire helix. Thermo-insulating covering in polyester fibre (thickness 25mm/16kg/m3), outer aluminized film protection (flame retardant).

Read more -

SA10/ESP SLEEVE Mastersan

Insulating sleeve produced with exclusive technology by TECNICA SRL.

Read more -

DAM01C

Helical-effect diffuser with radially arranged adjustable deflectors with a high induction ratio (mixing capacity) between the injected and the ambient air. Made up of a plate with holes inside which adjustable plastic deflectors are housed suitable for use at high operating temperatures.

Read more

DHT

High-induction adjustable conical nozzle diffuser with direct duct mounting and EPDM sealing gasket. The central body can be easiliy adjusted or rotated 180° for maximum throw.

- INSTALLATION HEIGHT:: up to 25/30m

- APPLICATION: cooling and heating for wide areas

SPECIFICTIONS

• MATERIAL: Pickled Steel

• SURFACE FINISH: epoxy powder coating resistant to impact and abrasion

• COLOUR: RAL white 9010 glossy, 9016 glossy, 9003 mat. On request, coating in nonstandard RAL colours

• FASTENING: by means of screws positioned on the diffuser neck

GREEN BUILDING

Contribute to obtain the credits of the major international rating systems for suistainable buildings:

- LEED: IP, EA, MR

- WELL: MATERIALS, COMMUNITY

- BREEAM: MAN, WST

INSTALLATION

Adjustments and maintenance are simple to perform. The central conical nozzles are easily removable by acting on the external nuts. The channel fixing is carried out by means of screws from the neck of the diffuser.

ADJUSTMENT

Central conical nozzles in standard position: optimal position in cooling conditions in order to obtain a shallower throw with a greater amplitude. With this configuration you have the best conditions of pressure drop, speed and sound level. The maximum temperature difference (DT) between the ambient air and the air coming out of the diffuser to obtain the optimal induction conditions is 12 ° C.

Central conical nozzles rotated 180 ° inwards: optimal position for particularly high rooms, up to 25/30 m and in heating conditions as a maximum vertical throw is obtained which opposes the convective motion of the air in the environment .

DOWNLOAD TECHNICAL SHEET >>

Share

Related products

-

KF100/R

Synthetic flat filter cell far fan coils with U-section galvanised steel support and containment frame and double electrowelded galvanised wire mesh that supports the 10x 10 honeycomb filter fabric.

Read more -

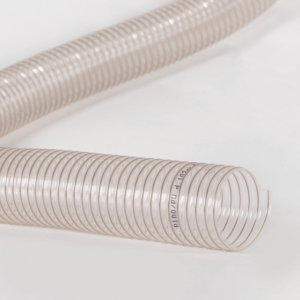

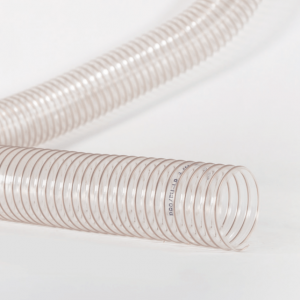

AR10 MASTERSAN

Flexible hose made of addivated polyolefin resins film reinforced with polyester mesh with anti-bacterial, anti-mildew and anti-viral material protection with steel wire helix.

Read more